Our journey from discarded plastic to valuable raw material continues beyond grinding. Here's how we convert recycled flakes into granules:

Transforming Flakes into Future-Ready Granules

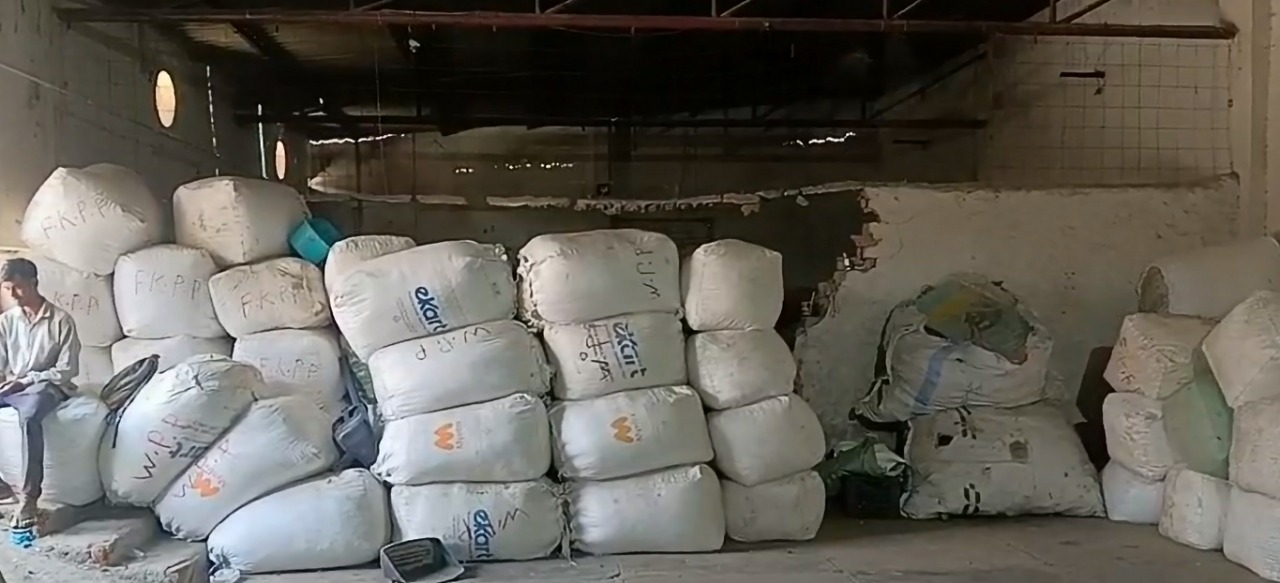

At Vibhuti Strength LLP, we take recycling one step further by converting cleaned and sorted plastic flakes into high-quality plastic granules. These granules are the essential building blocks for countless new products—and a major step toward closing the loop on plastic waste.

Through innovation, precision, and a strong commitment to sustainability, we produce granules that meet the industry’s highest standards—all from post-consumer plastic waste.

🧵 From Flake to Form – The Granulation Process

1. ✅ Pre-processing & Quality Check

Before entering the granulation line, plastic flakes undergo:

This pre-processing ensures our granules are pure, uniform, and application ready.

2. ♨️ Melting & Extrusion

Cleaned flakes are fed into our plastic extruder machine, where:

Our process uses advanced temperature regulation and filtration systems to maintain polymer integrity and remove impurities.

3. ✂️ Granule Cutting

The molten strands are then:

These granules are typically 2-5 mm in diameter, depending on end-use requirements.

4. 📦 Screening, Drying & Packaging

Post-cutting, granules go through:

🏭 Applications of Our Recycled Granules

Our granules are supplied to various manufacturers who use them in:

We also use these granules in-house to manufacture our own products like:

🌍 Why It Matters – Impact of Granulation

✅ Supports a circular economy

Each batch of granules represents plastic saved, pollution prevented, and value restored.

🌱 Powered by Waste. Designed for Impact.

At Vibhuti Strength LLP, we believe that waste is not the end of the line—it’s the beginning of a new cycle. Our recycled plastic granules offer a sustainable, cost-effective, and high-quality alternative to virgin plastic across industries.

📦 Looking for reliable recycled plastic granules?

Let’s build a cleaner future together.